info@bgp-group.co.uk

BGP 205 Mini Compact Wheeled Paver

Latest Model Launch - BGP 205

| Capacities | |

| Hopper Capacity : | 6.6 tons |

| Hydraulic System : | 106 Litres |

| Fuel Tank : | 78 Litres |

| Material Throughout - Theoretical | 186 TPH |

| Production Rate : | 120 TPH |

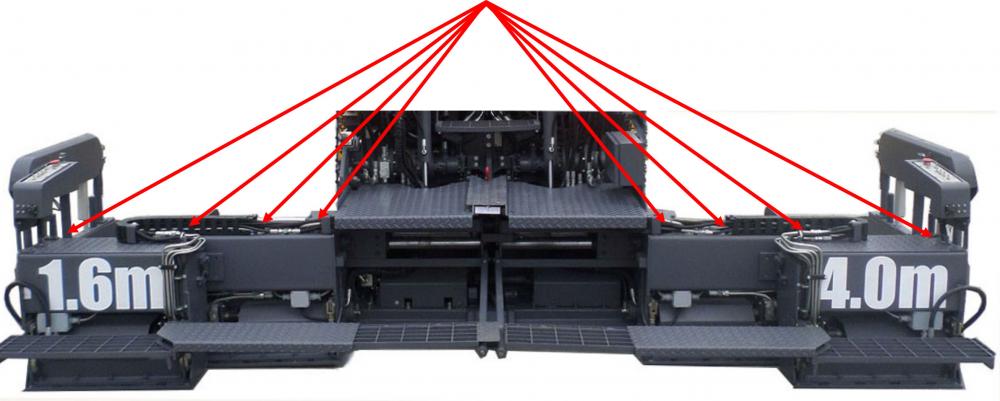

| Hydraulic Paving Width : | 1.6m-4.0m - Layer |

| Paving Depth : | 0-150mm |

| Travel Speed : | 0-10km/hr |

| Standard Engine | Kubota-Water Cooled / 4 Cylinder |

| Rated Output : | 37KW / 2600 HP |

Features and Benefits

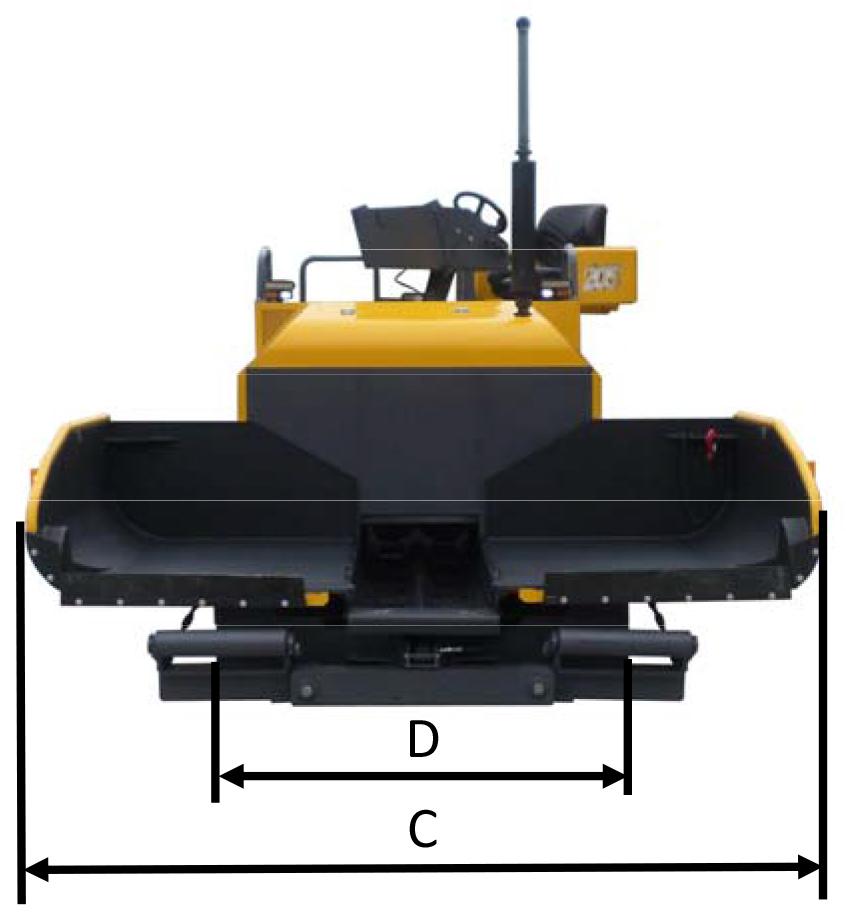

The all new BGP 205 is an ultra compact wheeled paver with a basic envelope machine width of 1.6 metres,the BGP 205 is an ideal fit for footpaths, cycle ways, car parks, narrow lanes etc with room to spare.

This machine is equipped with a double extension screed unit providing on the move hydraulic paving width from 1.6-4.0 metres. Each screed extension is able to be trimmed effortlessly on the move to ensure correct allignment to the main screed section.

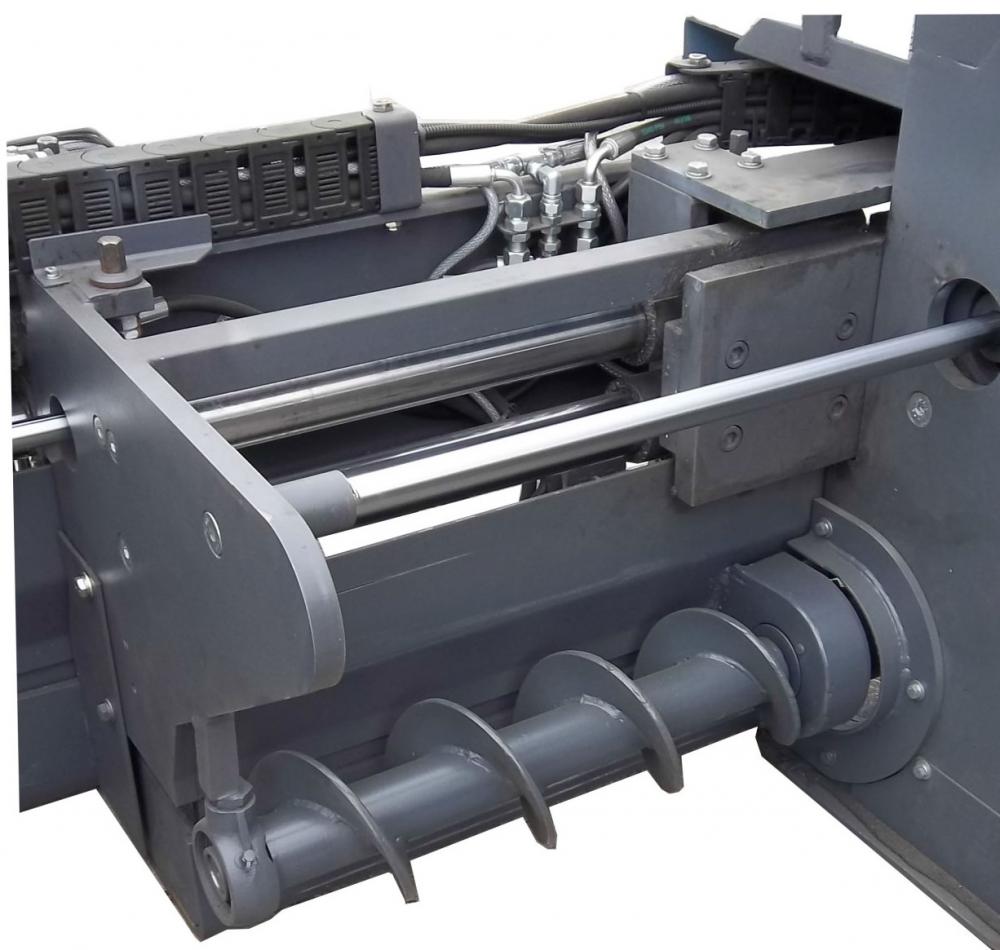

A main feature of the BGP 205 is the primary 1st stage screed extensions, each are equipped with their own Auger section, this gives a constant material flow to both the primary screed extension and the secondary screed extension.

The BGP 205 boasts very impressive traction, the machine is equipped with a high torque ratio planetary drive system mounted within an over wide (380mm) hydroflated footprint drive tyre. The substantial tractive effort is complemented further with a full time hydraulic front wheel drive system which receives additional boost from the automatic timed engagement of the hydraulic differential lock when paving commences from a standing start.

The BGP 205 also acheives exceptional manouevrability from its close dimensioned wheel base, large diameter single wheel pivot steer radius and its ability to spin turn within its own compact length.

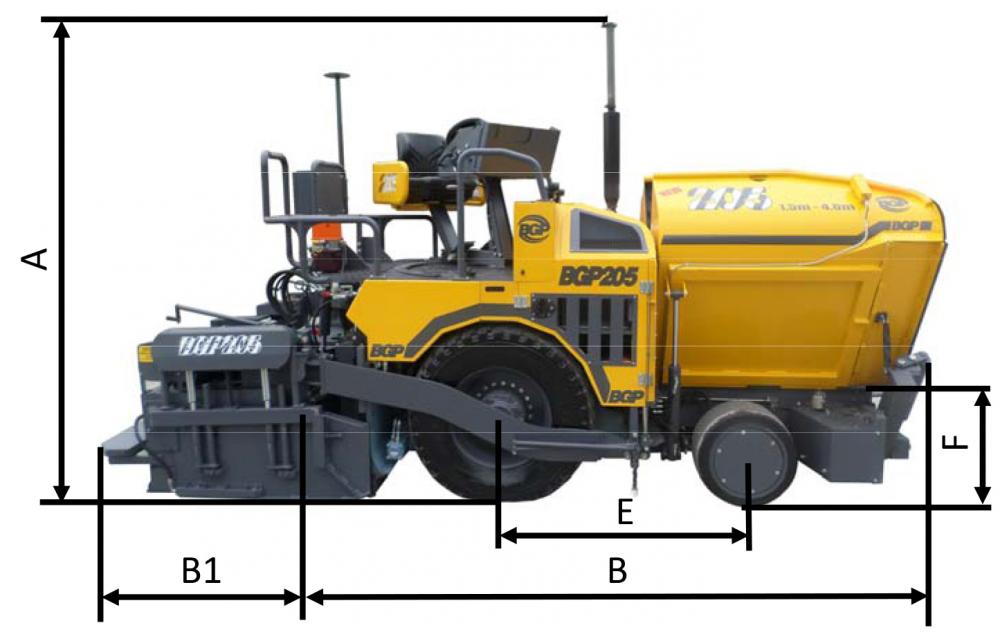

| A | B | B+B1 | C | D | E | F | G |

|

Minimum Height |

Length | Length | Width | Wheel Base | Axle Base | Truck Entry | Machine Weight |

|

Operating 2.83m |

Tractor Unit Only 3.48m |

With16-40 Screed 4.71m |

Operating 2.82m |

External of Drive Tyres 1.54m |

Axle Centres 1.38m |

Hopper Floor 618mm |

5600 Kg |

|

Shipping 2.25m |

BGP V16 - 40 (Double Extension Screed unit)

The V16-40 screed unit is of sturdy construction. Each extension is equipped with its own individual torque arresting support rods of ample diameter to ensure screed allignment is maintained under the material load. Individual - inboard and outboard extension height adjustment jacks enables on the move trimming of the primary and secondary screed extensions to be a simple operation.

Height Adjusting Jacks

V16 - 40 Screed

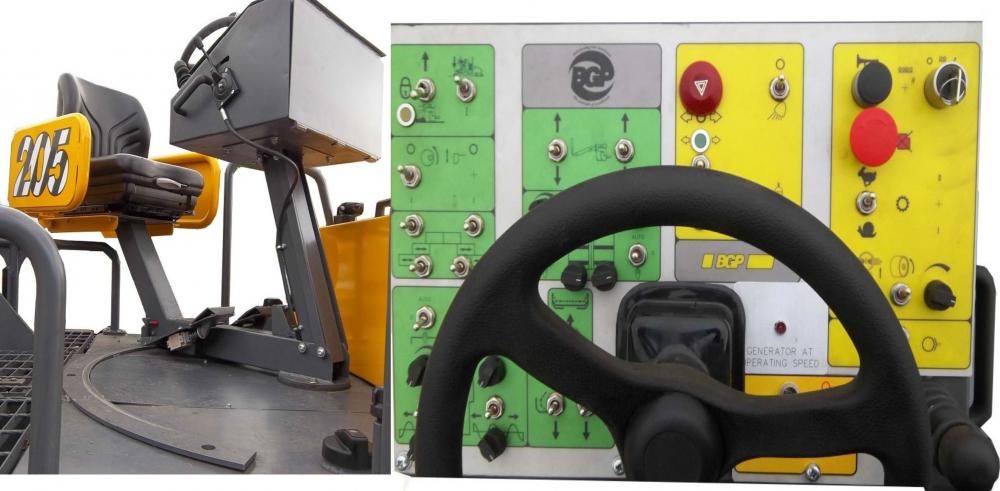

Operators Station and Drivers Console

The BGP 205's unique in built Auger extension is a very efficient and labour saving method of ensuring both the primary and secondary screed extension are supplied with a constant and sufficient vital head of material to keep the 205 Paving width fewer stop-start interuptions to the paving operation.